Development

In the development module you will find full support to optimize your developments. Test protocols, pre-calculation, cutting data, troubleshooting, tool life calculations, geometry data and much more.

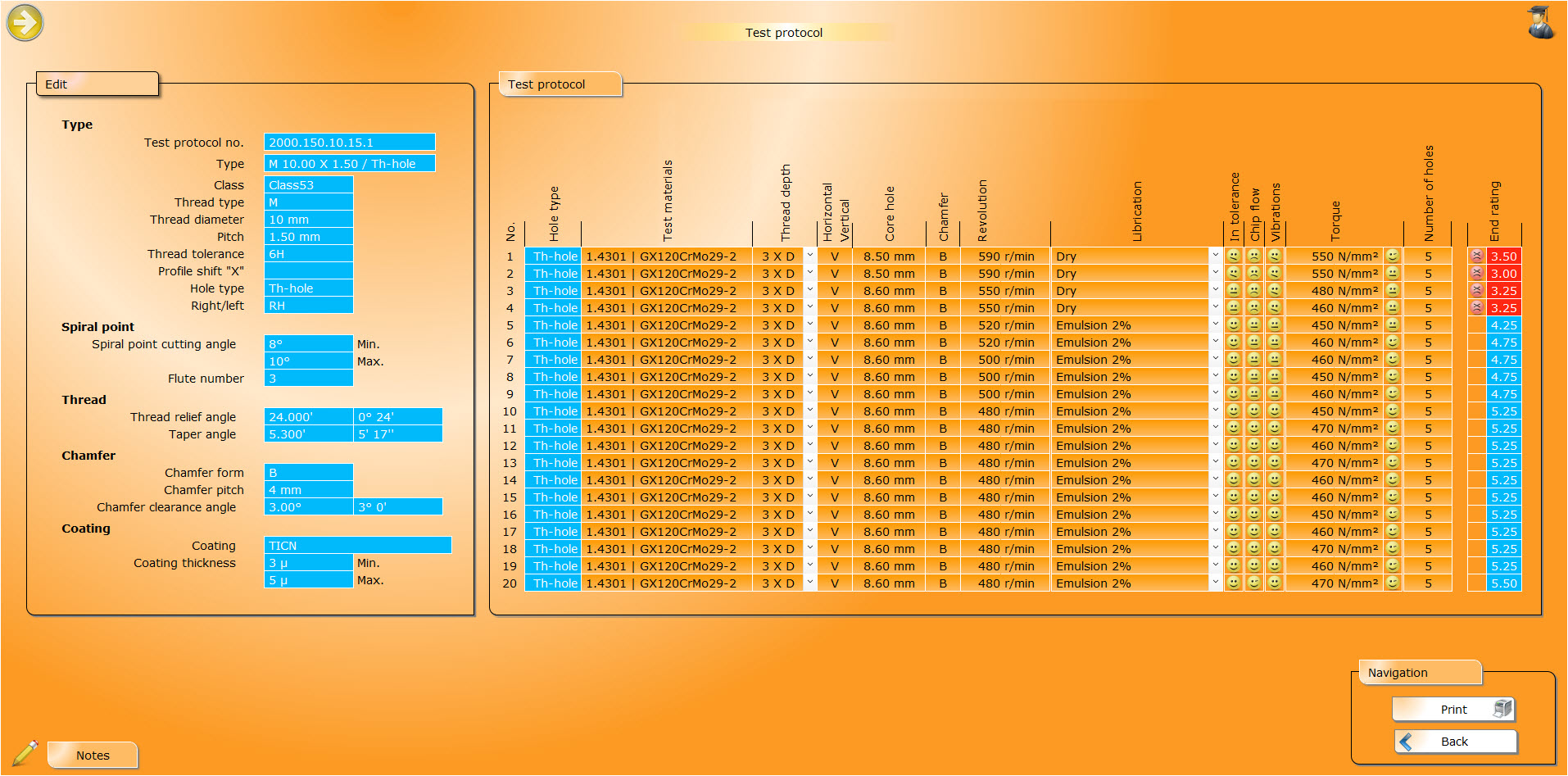

The development of taps also includes tests. This has to be done very carefully to be sure that the development can be released for production.

In order to ensure a professional process, TapPro helps you with various tools. One of them is the test protocol that gives you a guideline for a safe release.

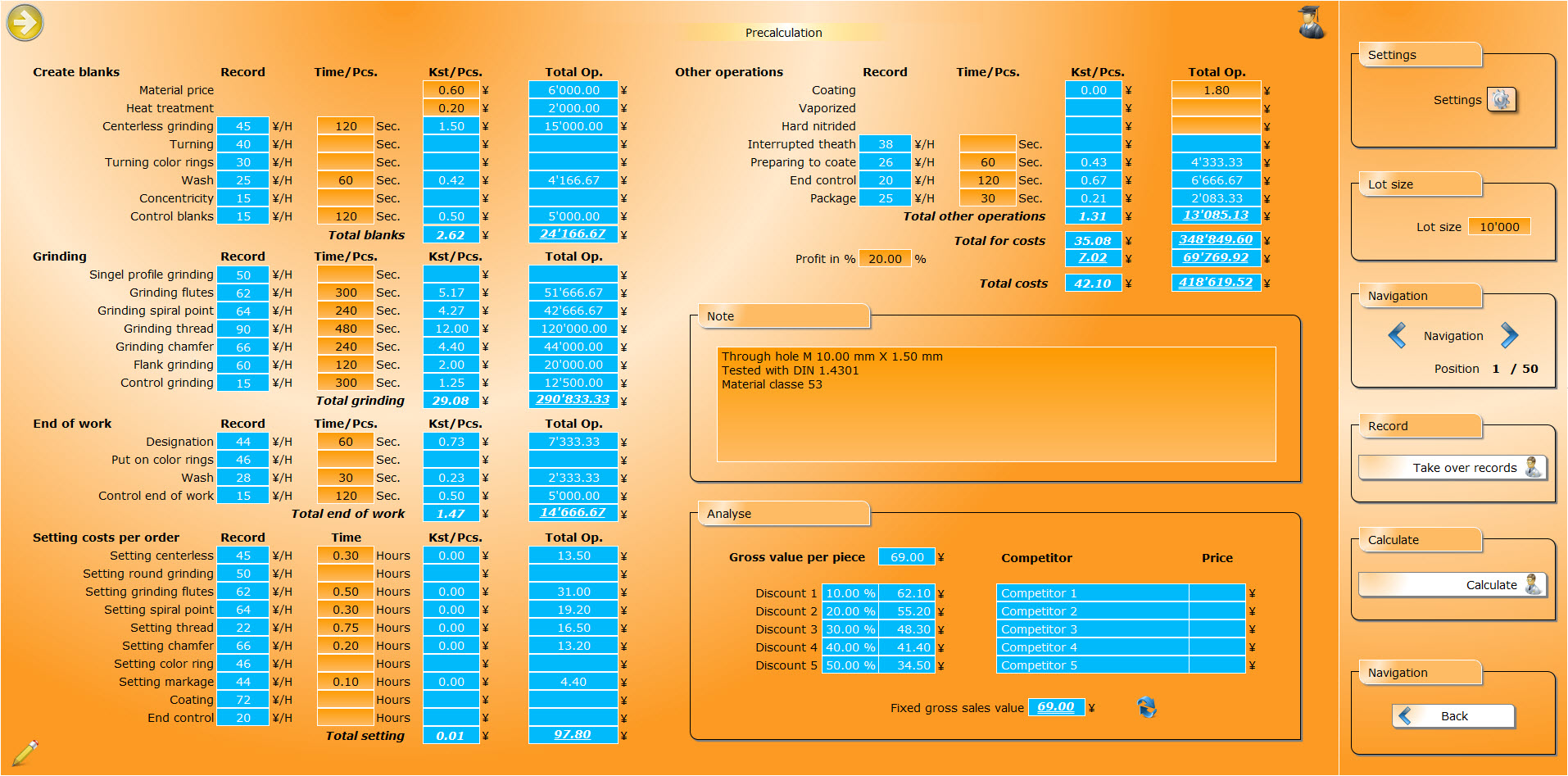

With TapPro you can make a pre-calculation to find out in which price segment you will be according to your production.

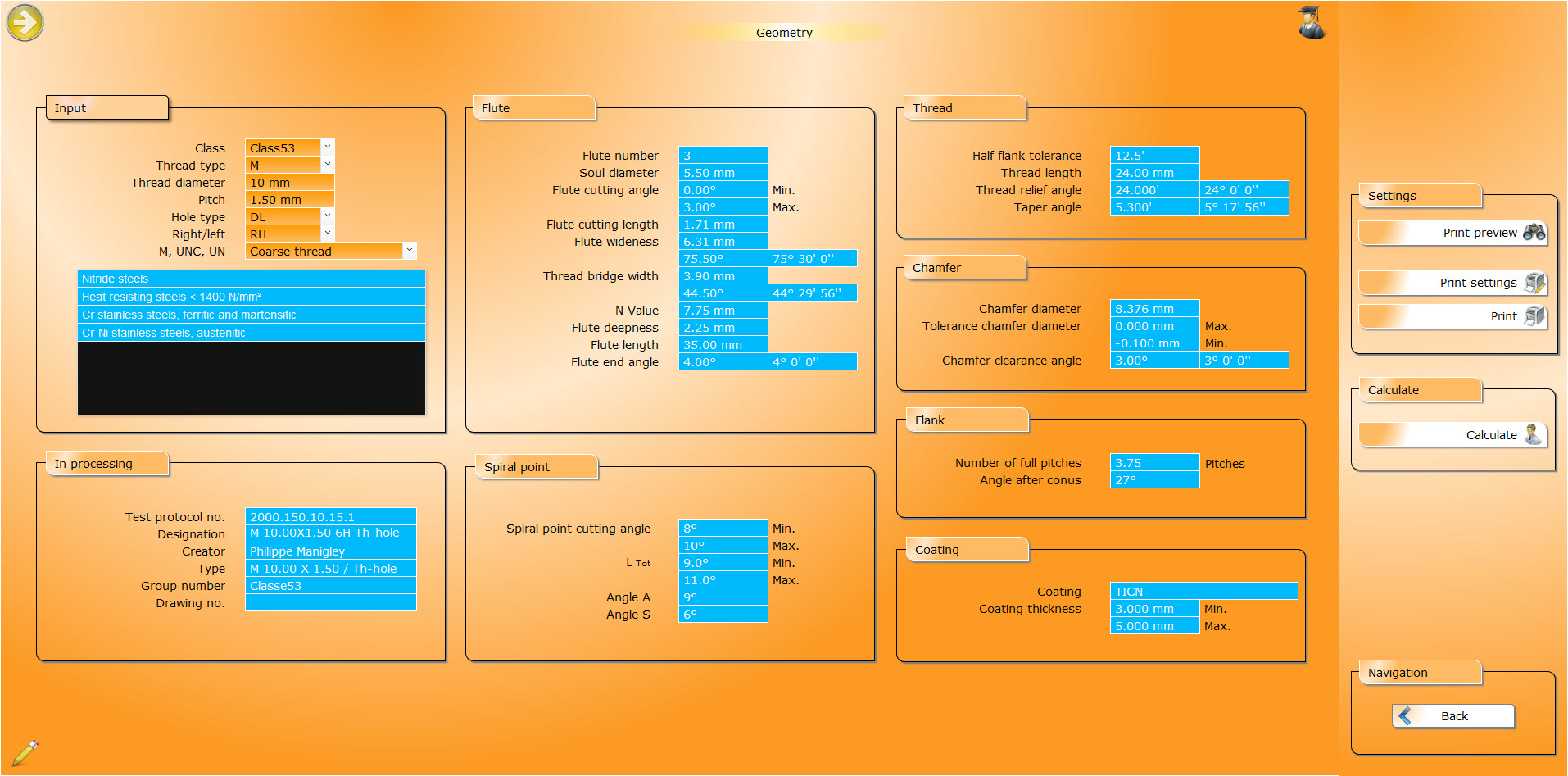

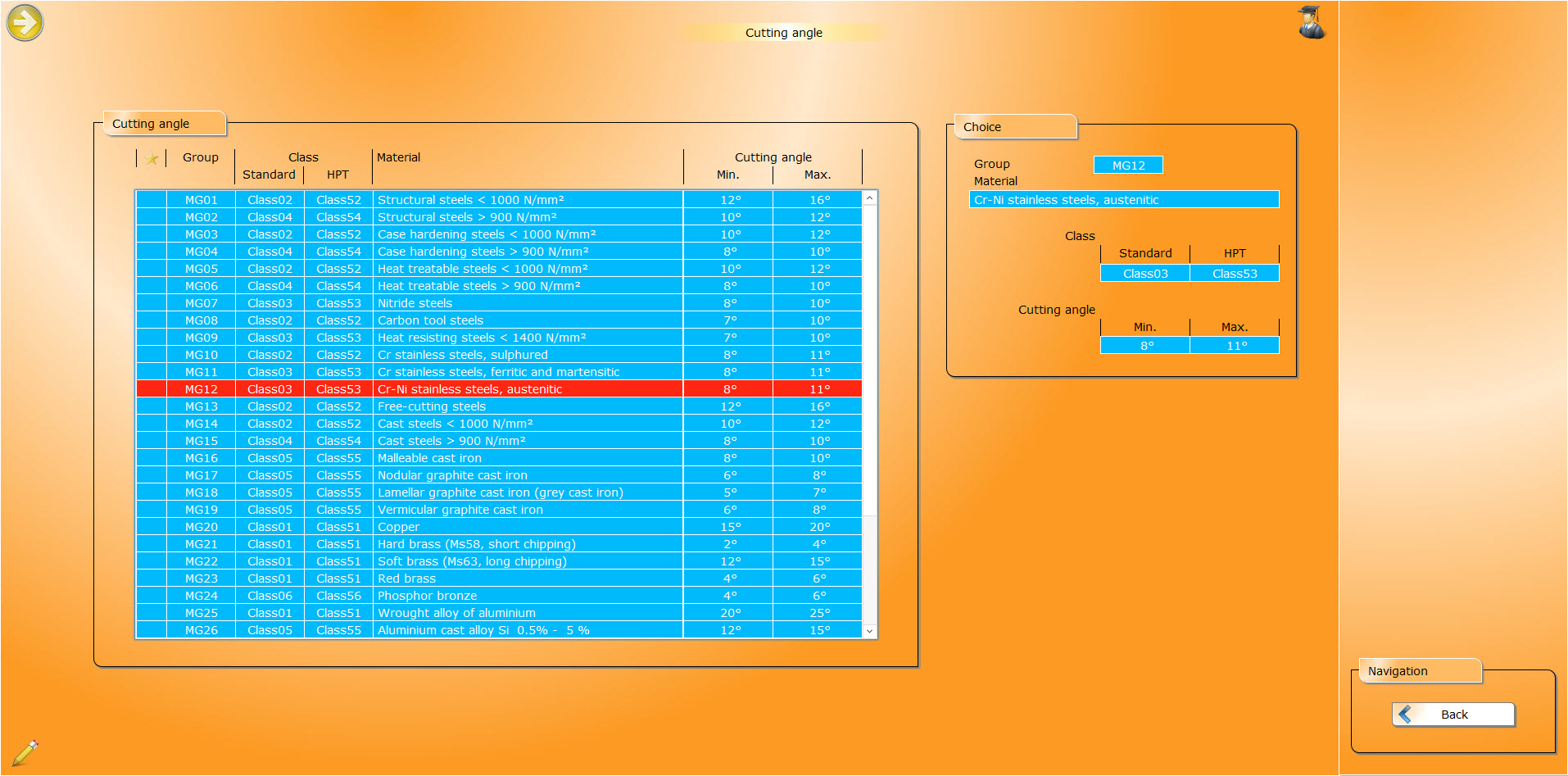

You can select the geometry value according to the material class of your development. However, if you create a tap with the module geometry you have to insert all necessary value.

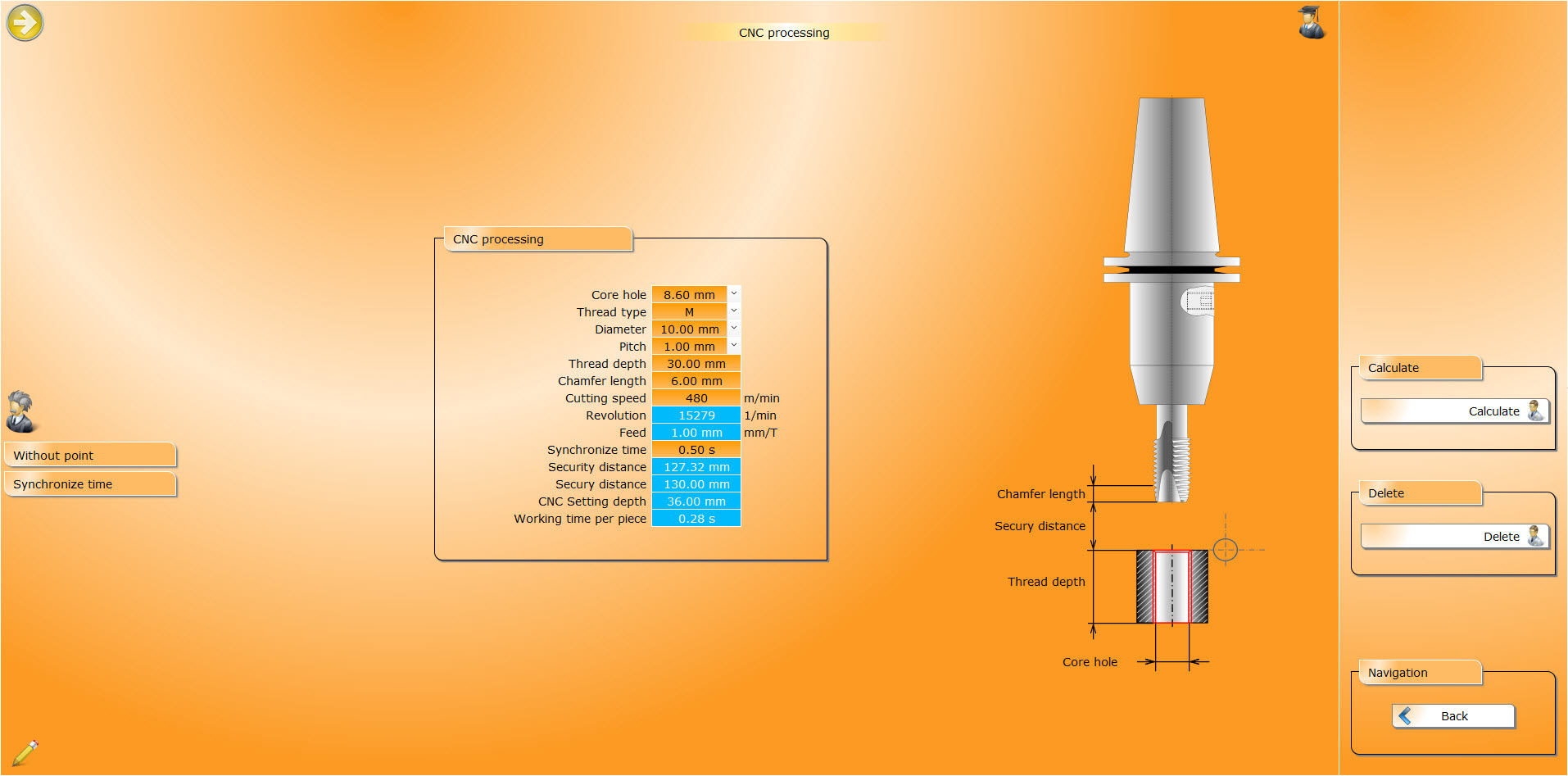

Under CNC Processing you can let TapPro calculate the settings for your test taps

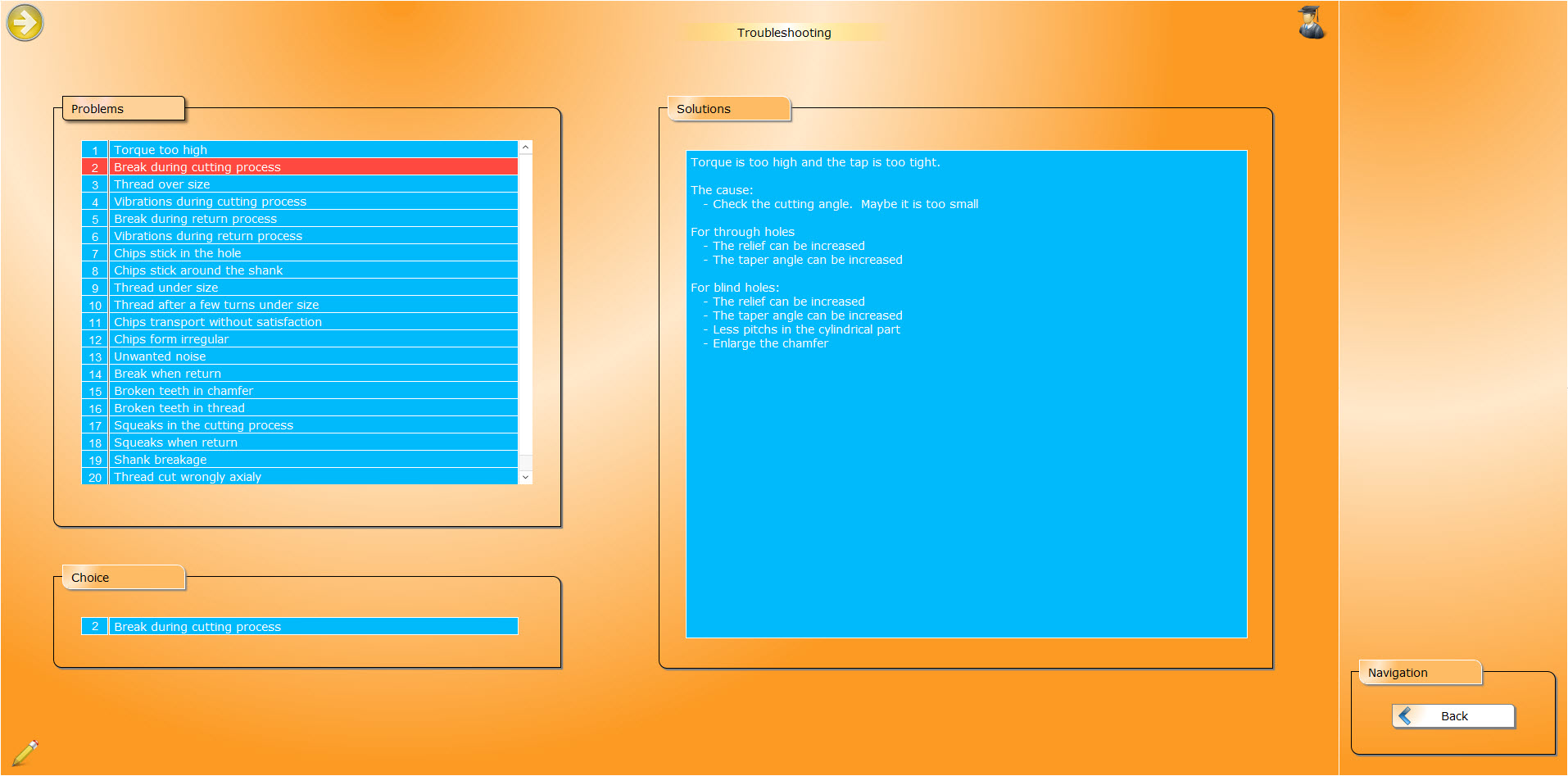

Sometimes you have to create 2 or more first series for testing until you will find the suitable tap for your material group. With troubleshooting you can select a lot of experience information. You can select the problem and you will get the solution.

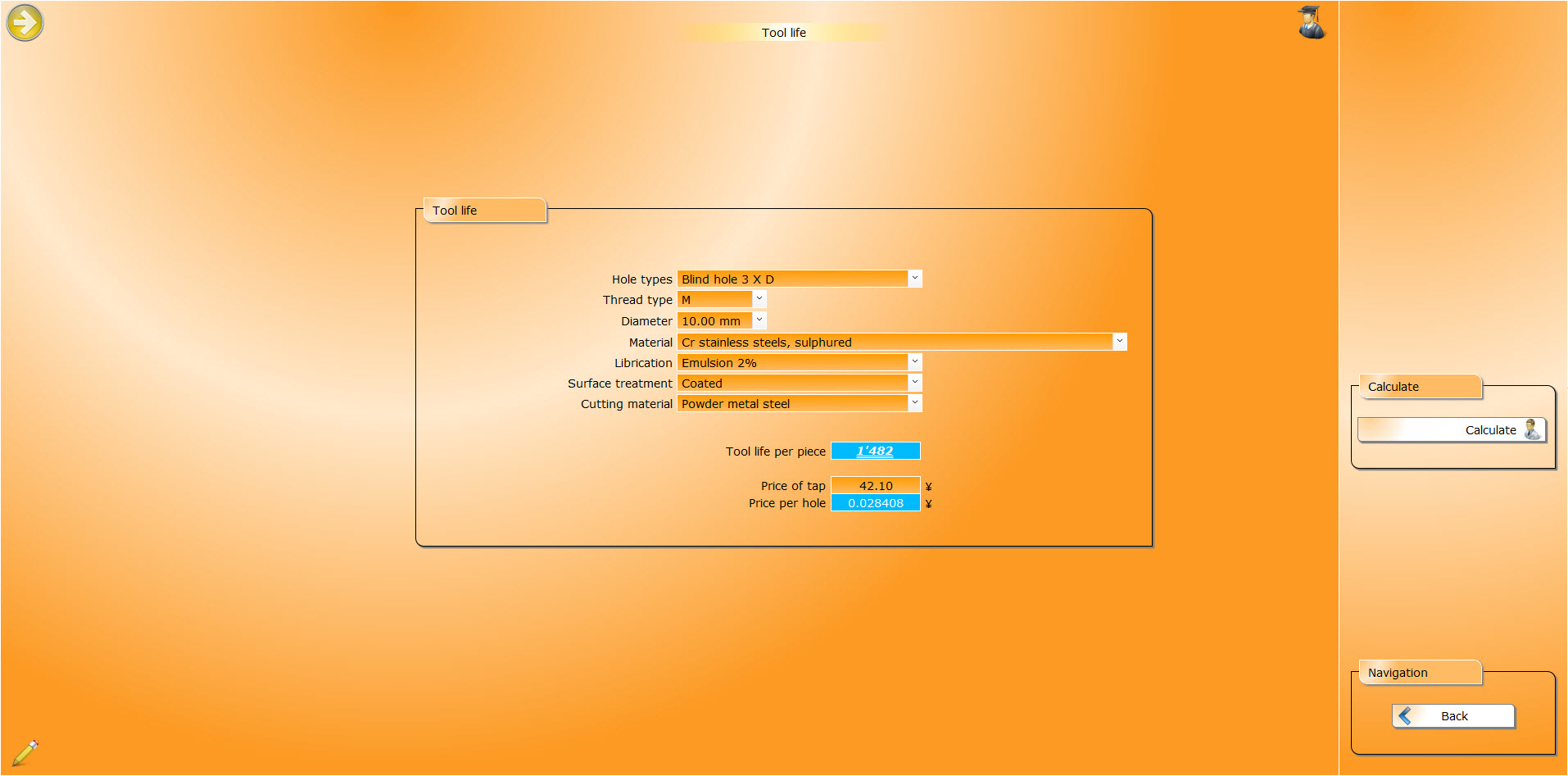

The tool life depends in large part of the way to use the tap it’s difficult to give some information about the lifetime of a tap. However, TapPro has a module to evaluate the tool life. You input the working conditions and the software will calculates it. The adjusting of the calculation can be done under the module administration.

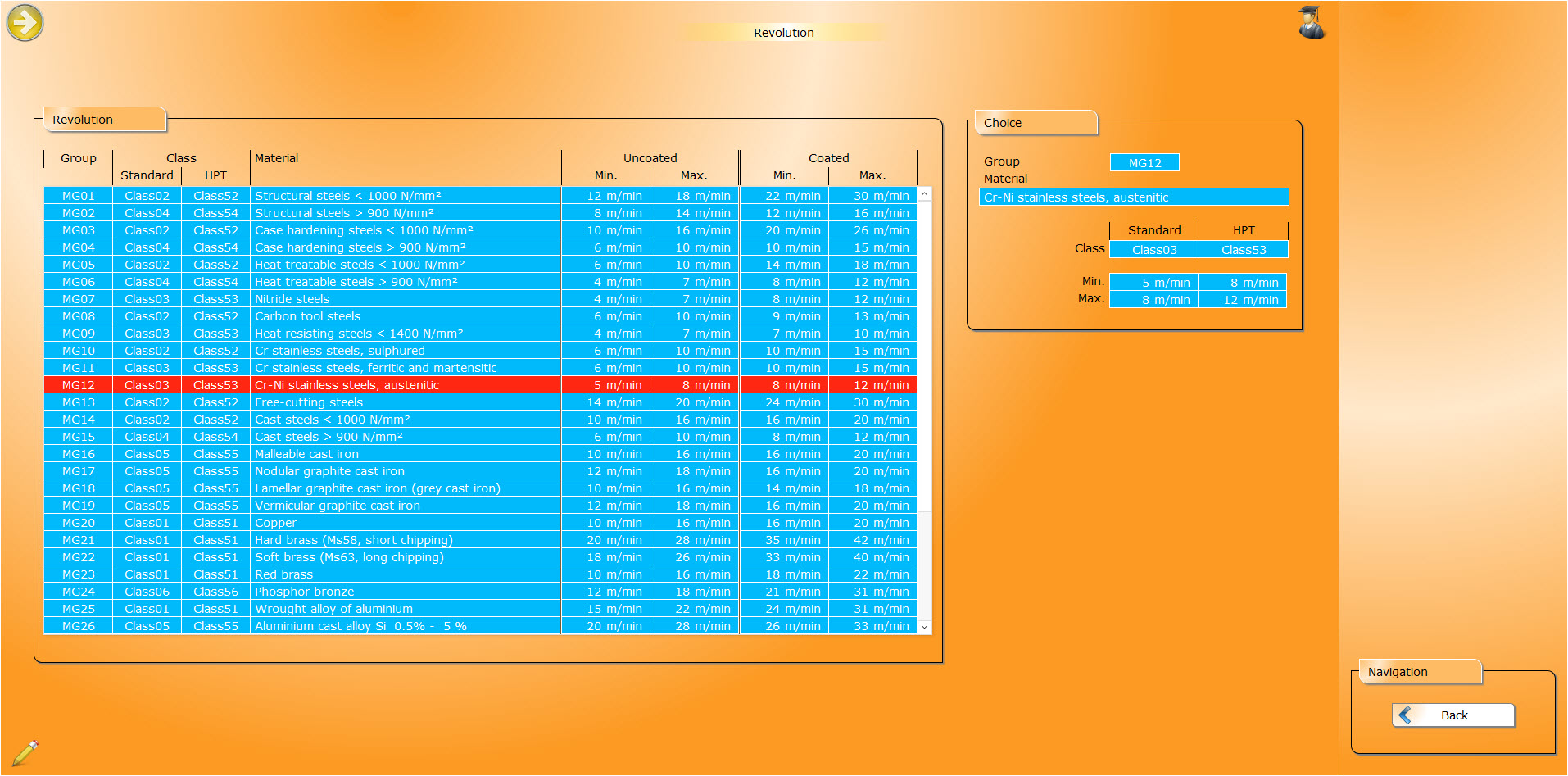

TapPro gives you the revolution according to the material group

TapPro gives you the cutting angle for your tap development. However, if you create a tap with the module geometry you have to insert all necessary value.

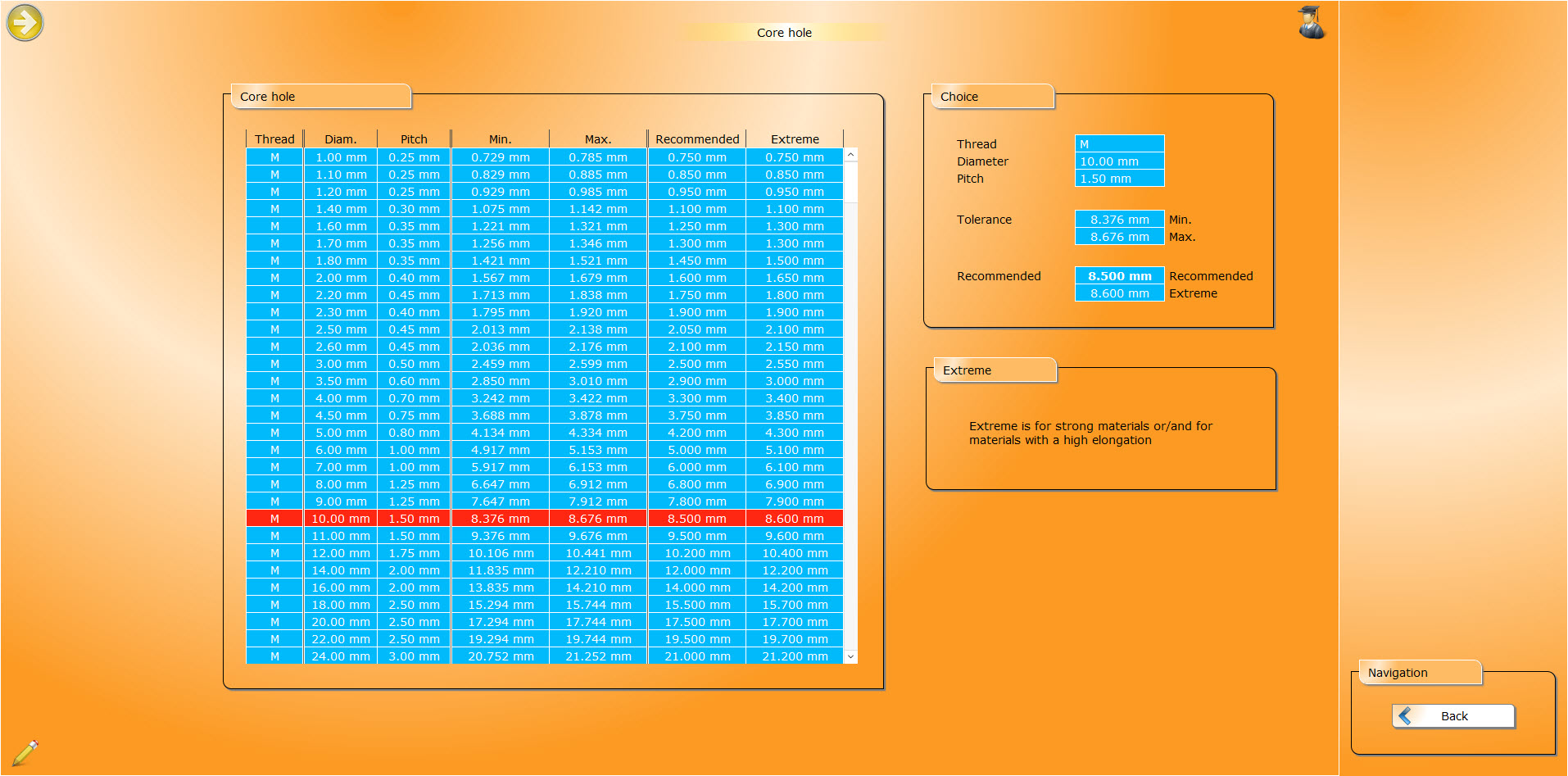

TapPro gives you the core hole diameter.