Geometry

The geometry is the most complicate part of the tap. TapPro gives all the information needed to develop a high performance tap according to the material class. For example, the thread relief angles, the back tapes, the cutting angles and all needed parameters to be successful. Finish with testing 3 to 6 series in order to find out the adequate geometry. The software gives you all the information to calculate the geometry in less than 5 minutes.

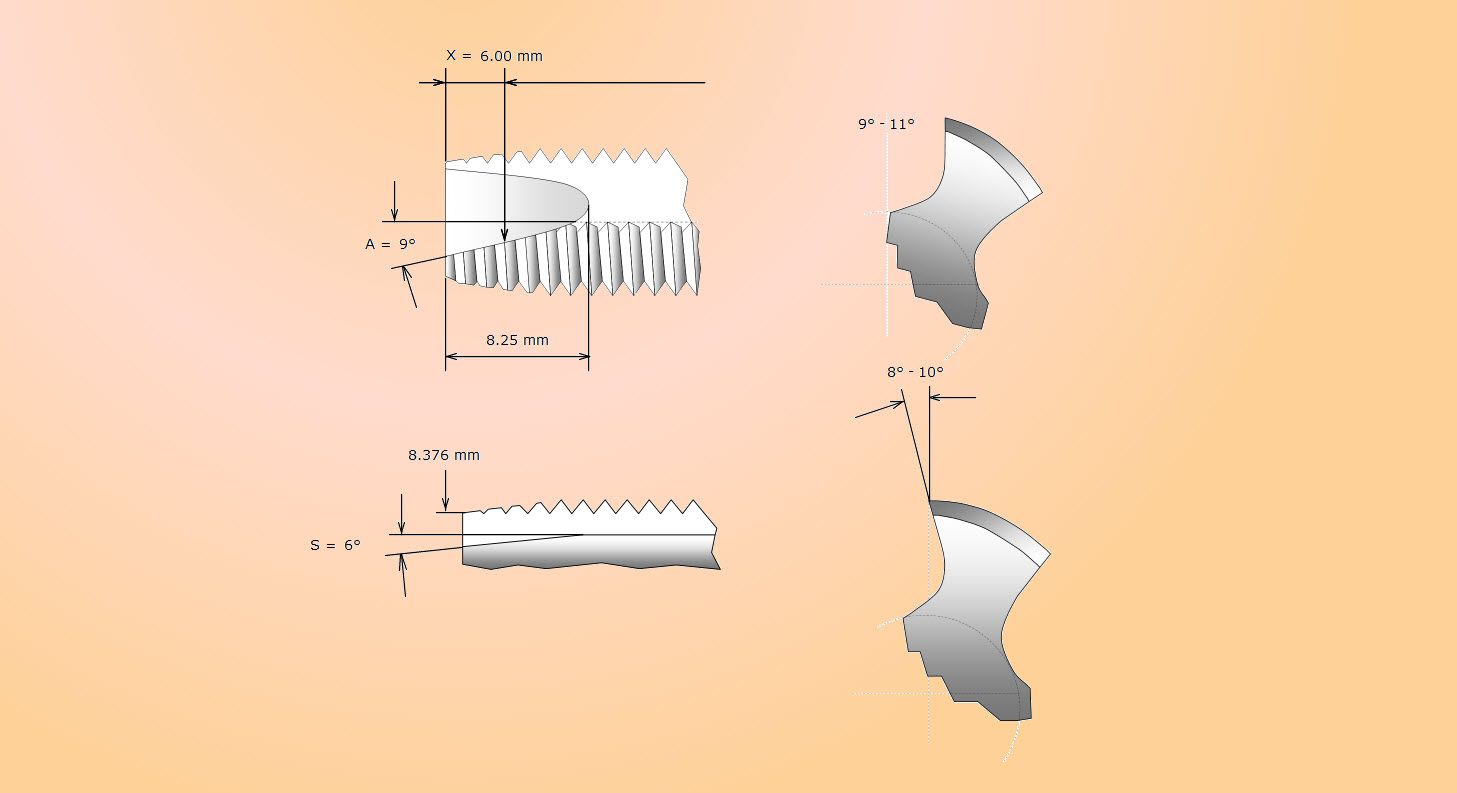

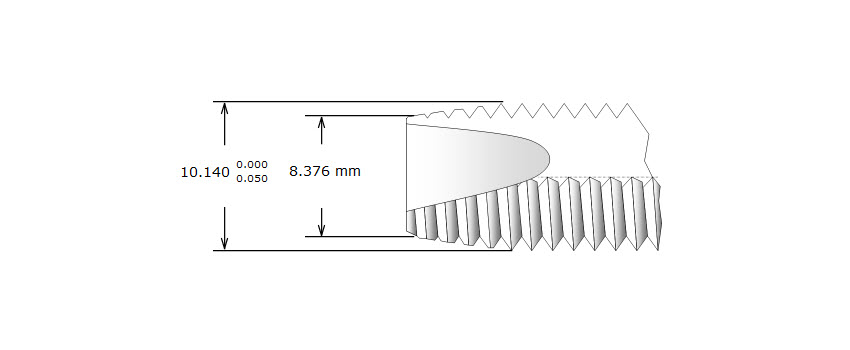

See the calculated geometry with TapPro for a high performance tap M 10.00 mm X 1.50 mm:

- M 10.00 mm X 1.50 mm

- Class53

- High performance Tap

- Stainless steels

- Tolerance 6H

- Th-hole

- Chamfer form B4

The geometry is the most complicate part of the tap. TapPro gives all the information needed to develop a high performance tap according to the material class. For example, the thread relief angles, the back tapes, the cutting angles and all needed parameters to be successful. Finish with testing 3 to 6 series in order to find out the adequate geometry. The software gives you all the information to calculate the geometry in less than 5 minutes.

See the calculated geometry with TapPro for a high performance tap M 10.00 mm X 1.50 mm:

- M 10.00 mm X 1.50 mm

- Class53

- High performance Tap

- Stainless steels

- Tolerance 6H

- Th-hole

- Chamfer form B4

Calculation of M 10.00 mm X 1.50 mm geometry

• Spiral point

• Thread dimensions

• Division relief in thread

• Back tape

• Chamfer

• Shank

Outside diameter

Chamfer diameter

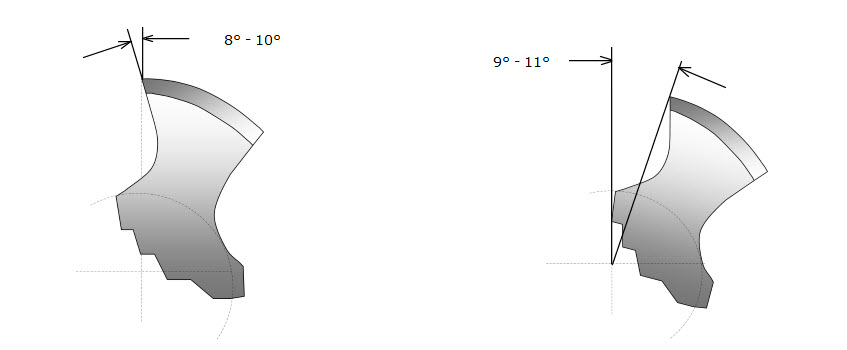

Spiral point cutting angle min.

max.

Inclination min.

max.

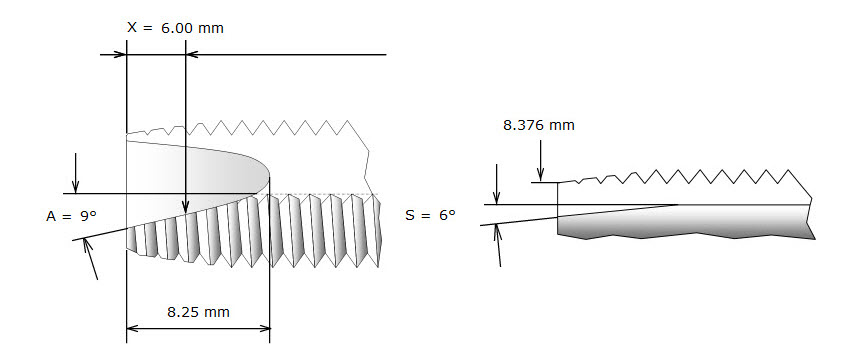

Angle A

Angle S

Spiral point length

Value x

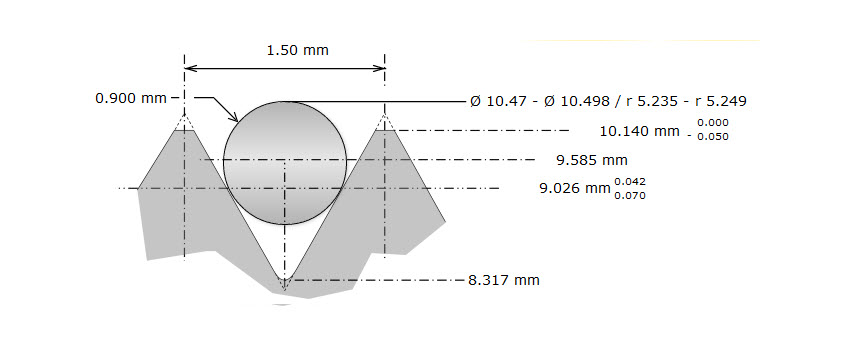

Outside diameter

Upper value

Lower value

TD2 Bolt

TD2 Screw

Flank diameter

Size tolerance 1

Size tolerance 2

Middle flank diameter

Theorical wire diameter

Measuring wire diameter

Measuring wire flank diameter

Measuring wire flank radius

Wire axis

Core diameter

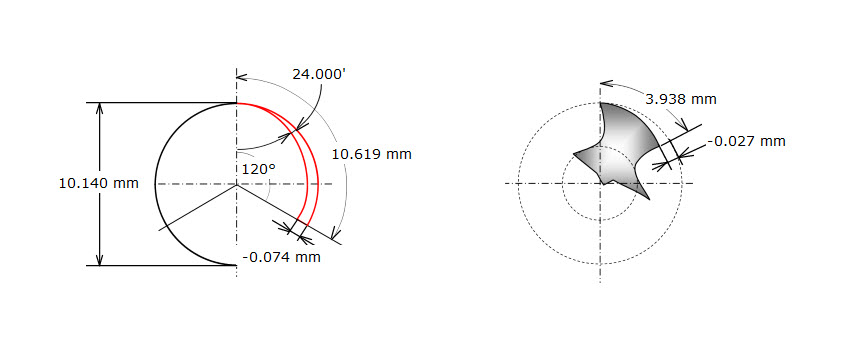

Pitch angle

Half flank angle

Half flank tolerance

Inclined position Cw

Thread bridge width

Thread relif angle

Division

Division relieve in thread

Radians on division

Radians thread bridge width

Relief after thread bridge width

Thread length

Taper angle

Diameter of back tape

Radius of back tape

Chamfer diameter

Tolerance chamfer diameter

Leer

Chamfer length

Leer

Setting angle

Thread relief angle

Division relief

Marking 1st line

Marking 2nd line

Marking 3rd line

10.140 mm 0.000 / -0.050

8.376 mm

8°

10°

9°

11°

9°

6°

8.25 mm

6.00 mm

10.140 mm 0.000 / -0.050

0.140 mm

0.090 mm

0.140 mm

0.180 mm

9.026 mm

0.042 mm

0.070 mm

9.082 mm

0.866 mm

0.900 mm

10.471 mm min. / 10.499 mm max.

5.235 mm min. / 5.249 mm max.

9.585 mm

8.317 mm max.

3.010° / 3° 0′ 32″

30°

25′

0.0019 mm

3.900 mm

24.000′

120°

-0.074 mm

10.619 mm

3.938 mm

-0.027 mm

24 mm

5.300′

-0.075 mm

-0.037 mm

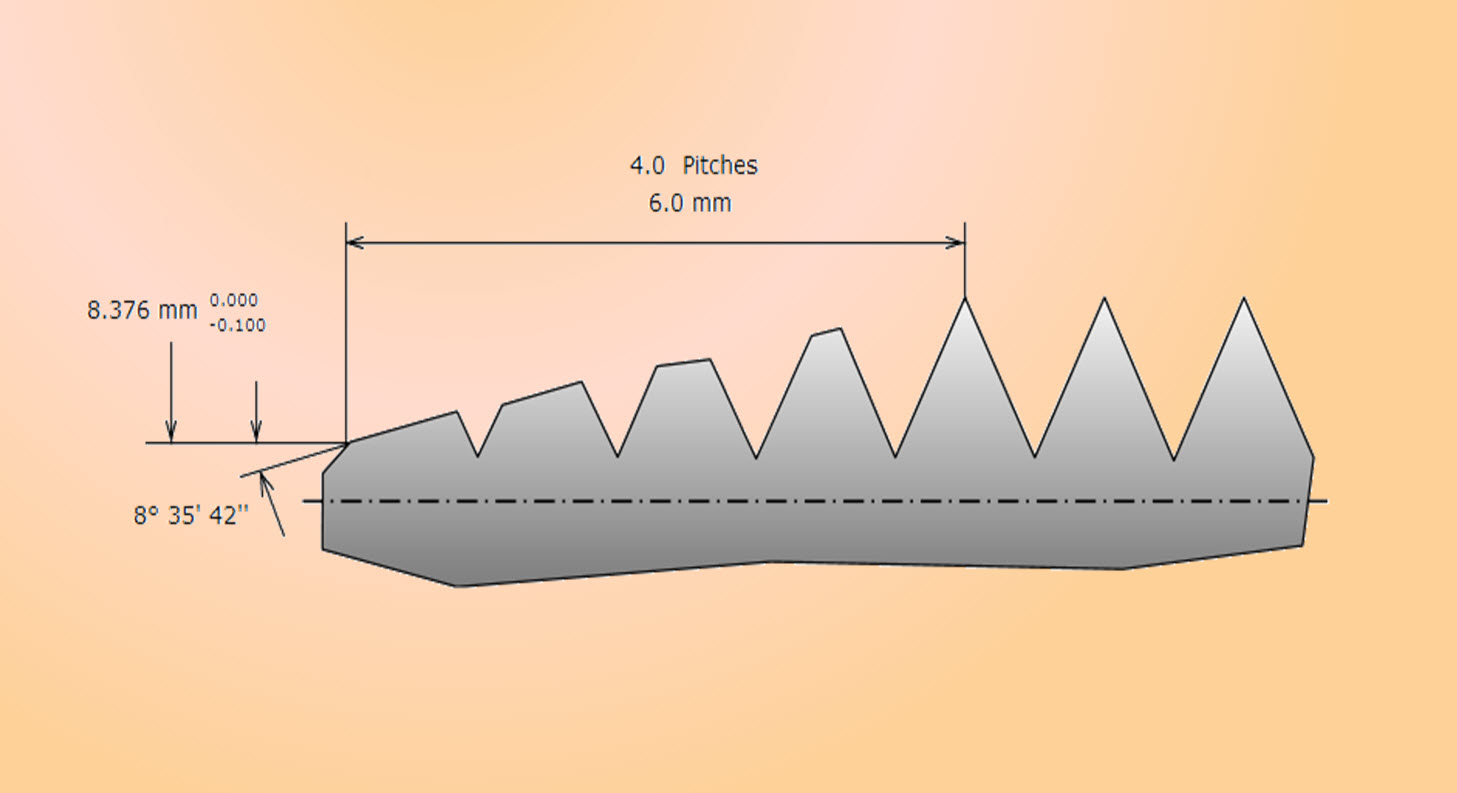

8.376 mm

0.000 mm

-0.100 mm

4.0 pitches

6.00 mm

8.598° / 8° 35′ 42″

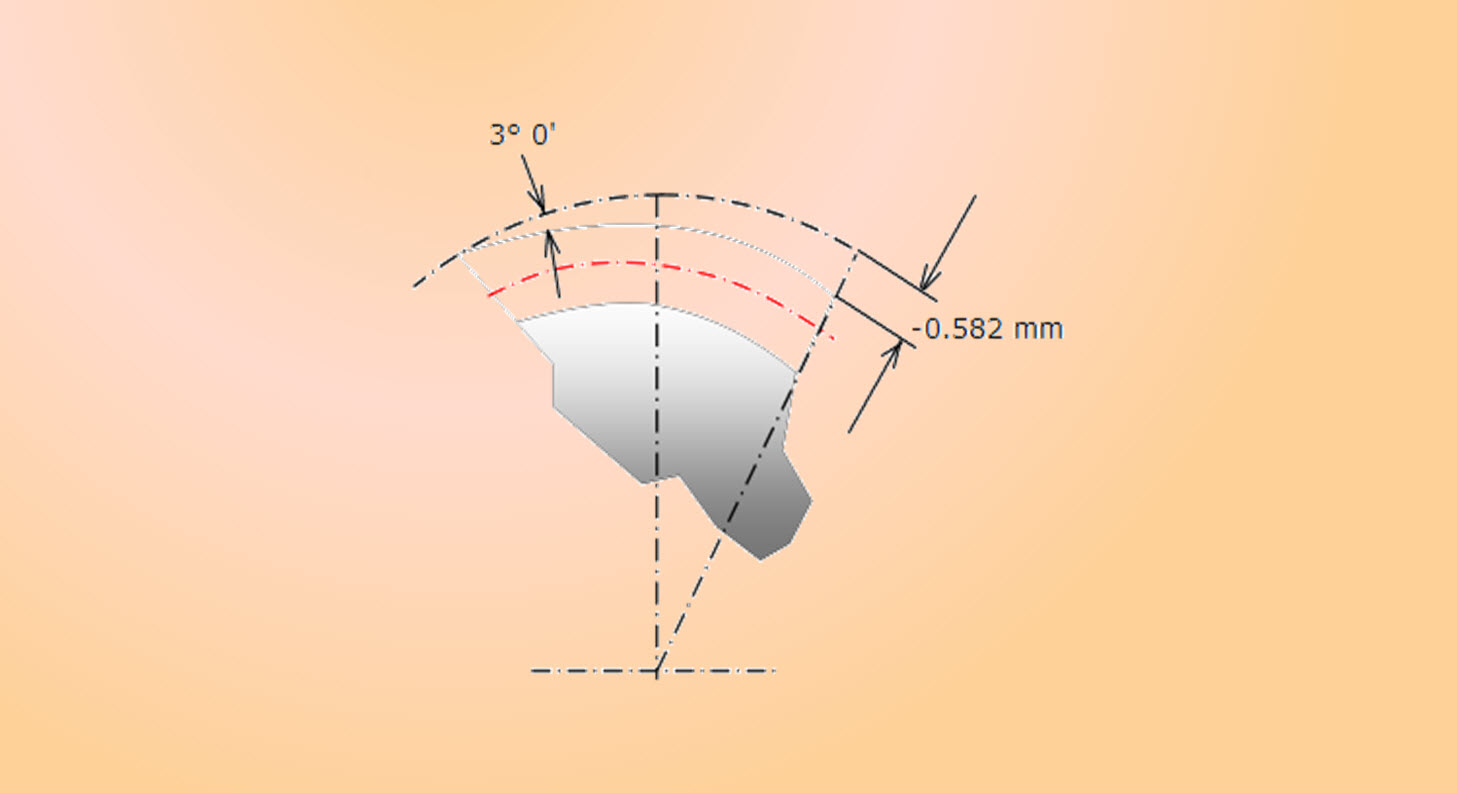

3.00° / 3° 0′ 0″

-0.582 mm

M 10.00 mm X 1.50 mm

B/4 DIN 376

Calculated by TapPro

Information

• All value in blue are proposed by the Genius

• All value in white are calculated by TapPro

• All values in gold are to be entered by the developer

Taps for helicopter

Taps for trucks

Taps for ships

Taps for cars

Information

• All value in blue are proposed by the Genius

• All value in white are calculated by TapPro

• All values in gold are to be entered by the developer

• Overview of the calculation with TapPro

Thread typeXXXXXXXXXXXXX

Designation

Creator

Type

Group number

Artical number

Drawing number

Test protocol number

Date

Time

Thread tolerance

Thread type

Flank angle

Half flank angle

Hole type

Thread diameter

Pitch

Multiple thread

Thread blank diameter

Profile shift «X»

Over mass

Chamfer form

Chamfer pitch

Flute number

Alternated teeth

Right/left

Cutting material

Cutting steel hardness

Hardening process

Class

Genius number

Coating

Coating thickness

Leer

MG-Group

Leer

M 10.00 X 1.50 6H Th-hole

Philippe Manigley

3000

3000 PM Classe53

250.10.15.1

2000.150.10.15.1

2000.150.10.15.2

27.05.2021

10:25:15

6H

M

60°

30°

Th-hole

10.00 mm

1.50 mm

1

10.30 mm

0.000 mm

0.000 mm

B

4

3

No

RH

HSSE-PM

HRc 66

Vaccum

Classe53

1101

TICN

3 μ min.

5 μ max.

MG07, MG09, MG11, MG12

Spiral pointXXXXXXXXXXXXX

Chamfer diameter

Spiral point cutter angle

Leer

Angle A

Angle S

Spiralpoint length

X

Inclinaton

Leer

Leer

ThreadXXXXXXXXXXXXXXXX

Outside diameter

Upper value

Lower value

TD2 Bolt

TD2 Screw

Flank diemeter

Size tolerance 1

Size tolerance 2

Middle flank diameter

Theorical wire diameter

Mesuring wire diameter

Mesuring wire flanc diameter

Mesuring wire flanc radius

Wire axis

Core diameter

Pitch angle

Leer

Leer

Half flank angle

Half flank tolerance

Inclined position Cw

Leer

8.376 mm

8° min.

10° max.

9°

6°

8.25 mm

6.00 mm

9° min.

11° max.

Leer

Leer

10.140 mm 0.000 / -0.050

0.140 mm

0.090 mm

0.140 mm

0.180 mm

9.026 mm

0.042 mm

0.070 mm

9.082 mm

0.866 mm

0.900 mm

10.471 mm min. / 10.499 mm max.

5.235 mm min. / 5.249 mm max.

9.585 mm

8.317 mm max.

3.010° / 3° 0′ 32″

30°

25′

0.0019 mm

Thread bridge width

Thread relif angle

Division

Division relieve in thread

Radians on division

Radians thread bridge width

Relief after thread bridge width

Thread length

Taper angle

Diameter of back tape

Radius of back tape

Leer

ChamferXXXXXXXXXXXXXXX

Chamfer diameter

Tolerance chamfer diameter

Leer

Chamfer length

Leer

Setting angle

Thread relef angle

Division relef

Leer

Leer

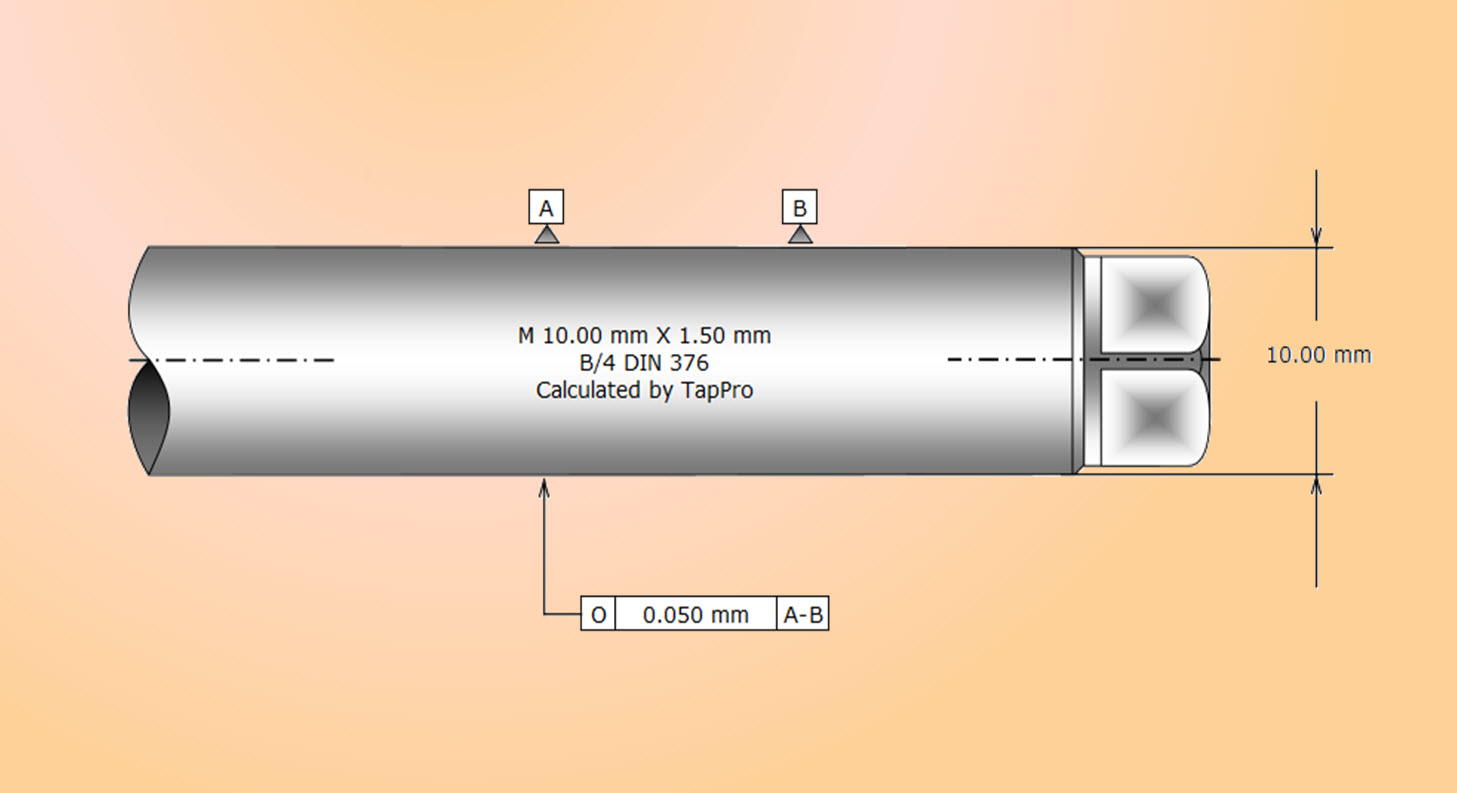

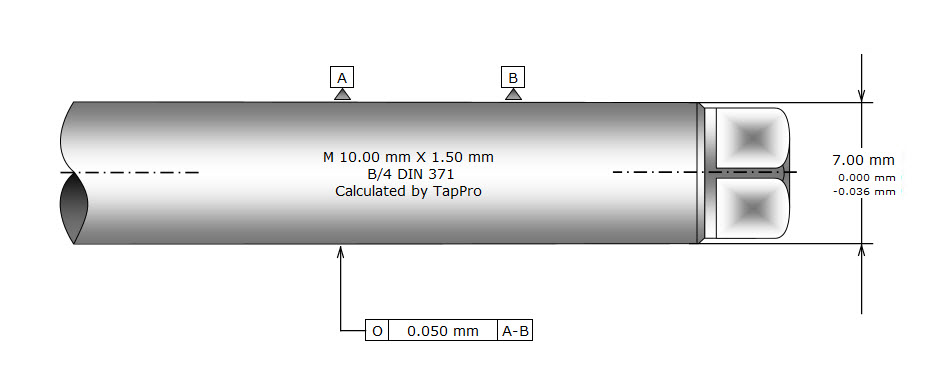

ShankXXXXXXXXXXXXXXXXX

Norm

Concetricity thread/shank

Shank diameter

Tolerance class

Shank diameter tolerance

Leer

Leer

DesignationXXXXXXXXXXXXX

Marking 1st line

Marking 2nd line

Marking 3rd line

3.900 mm

24.000′

120°

-0.074 mm

10.619 mm

3.938 mm

-0.027 mm

24 mm

5.300′

-0.075 mm

-0.037 mm

Leer

Leer

8.376 mm

0.000 mm

-0.100 mm

4.0 pitches

6.00 mm

8.598° / 8° 35′ 42″

3.00° / 3° 0′ 0″

-0.582 mm

Leer

Leer

Leer

DIN 376

0.050 mm

7.000 mm

h9

0.000 mm max.

-0.036 mm min.

Leer

Leer

M 10.00 mm X 1.50 mm

B/4 DIN 376

Calculated by TapPro

• Overview of the calculation

Thread type

Designation: M 10.00 X 1.50 6H Th-hole

Creator: Philippe Manigley

Type: 3000

Group number: 3000 PM Classe53

Artical number: 250.10.15.1

Drawing number: 2000.150.10.15.1

Test protocol number: 2000.150.10.15.2

Date: 27.05.2021

Time: 10:25:15

Thread tolerance: 6H

Thread type: M

Flank angle: 60°

Half flank angle: 30°

Hole type: Th-hole

Thread diameter: 10.00 mm

Pitch: 1.50 mm

Multiple thread: 1

Thread blank diameter: 10.30 mm

Profile shift «X»: 0.000 mm

Over mass: 0.000 mm

Chamfer form: B

Chamfer pitch: 4

Flute number: 3

Alternated teeth: No

Right/left: RH

Cutting material: HSSE-PM

Cutting steel hardness: HRc 66

Hardening process: Vaccum

Class: Classe53

Genius number: 1101

Coating: TICN

Coating thickness: 3 μ min. to 5 μ max.

MG-Group: MG07, MG09, MG11, MG12

Spiral point

Chamfer diameter: 8.376 mm

Spiral point cutter angle: 8° min. / 10° max.

Angle A: 9°

Angle S: 6°

Spiralpoint length: 8.25 mm

X: 6.00 mm

Inclinaton: 9° min. / 11° max.

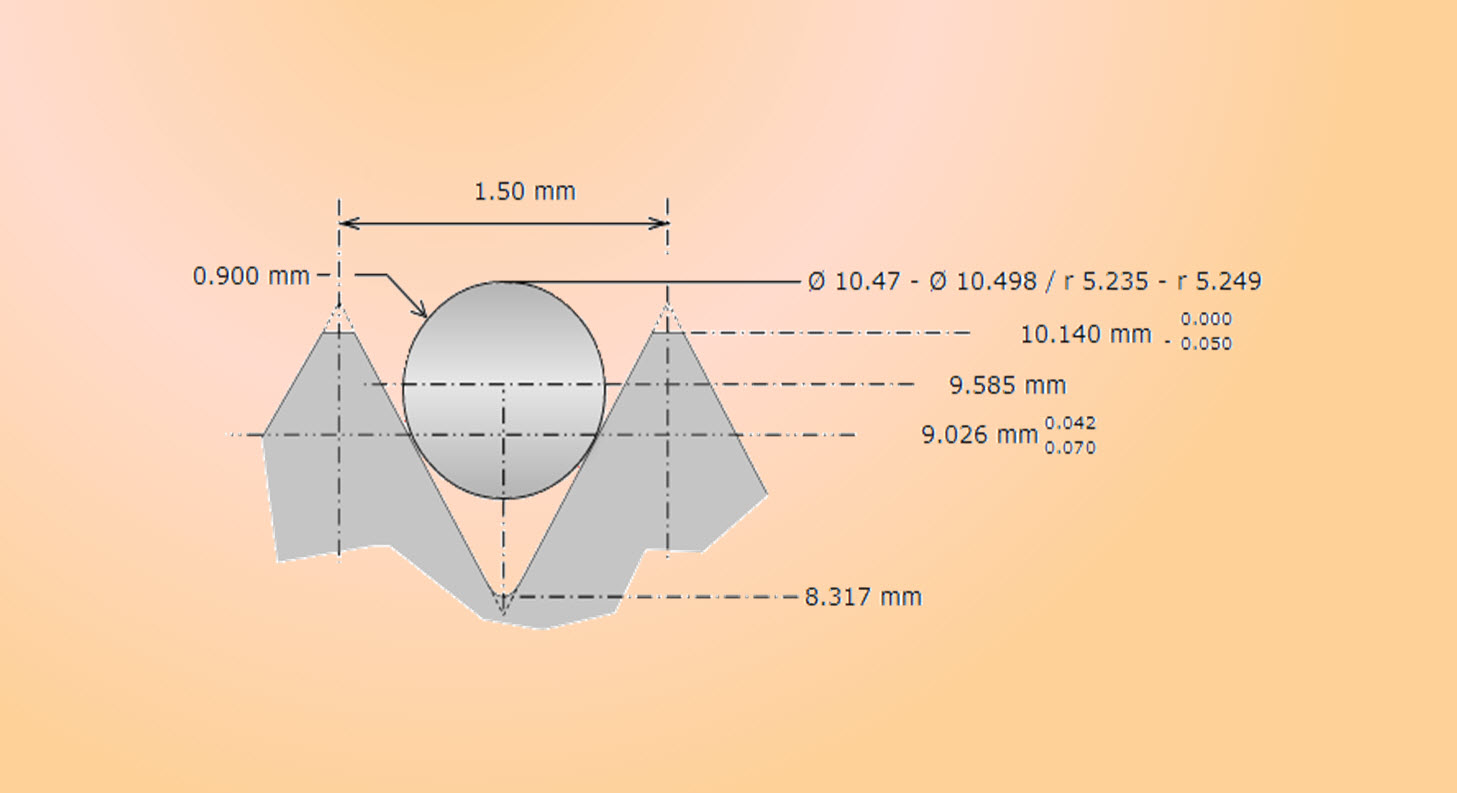

Thread dimensions

Outside diameter: 10.140 mm 0.000 / -0.050

Upper value: 0.140 mm

Lower value: 0.090 mm

TD2 Bolt: 0.140 mm

TD2 Screw: 0.180 mm

Flank diemeter: 9.026 mm

Size tolerance 1: 0.042 mm

Size tolerance 2: 0.070 mm

Middle flank diameter: 9.082 mm

Theorical wire diameter: 0.866 mm

Mesuring wire diameter: 0.900 mm

Mesuring wire flanc diameter: 10.471 mm min.

XXXXXXXXXXXXXXXXXXXXIII10.499 mm max.

Mesuring wire flanc radius: 5.235 mm min.

XXXXXXXXXXXXXXXXXXXI5.249 mm max.

Wire axis: 9.585 mm

Core diameter: 8.317 mm max.

Pitch angle: 3.010° / 3° 0′ 32″

Half flank angle: 30°Leer

Half flank tolerance: 25′

Inclined position Cw: 0.0019 mm

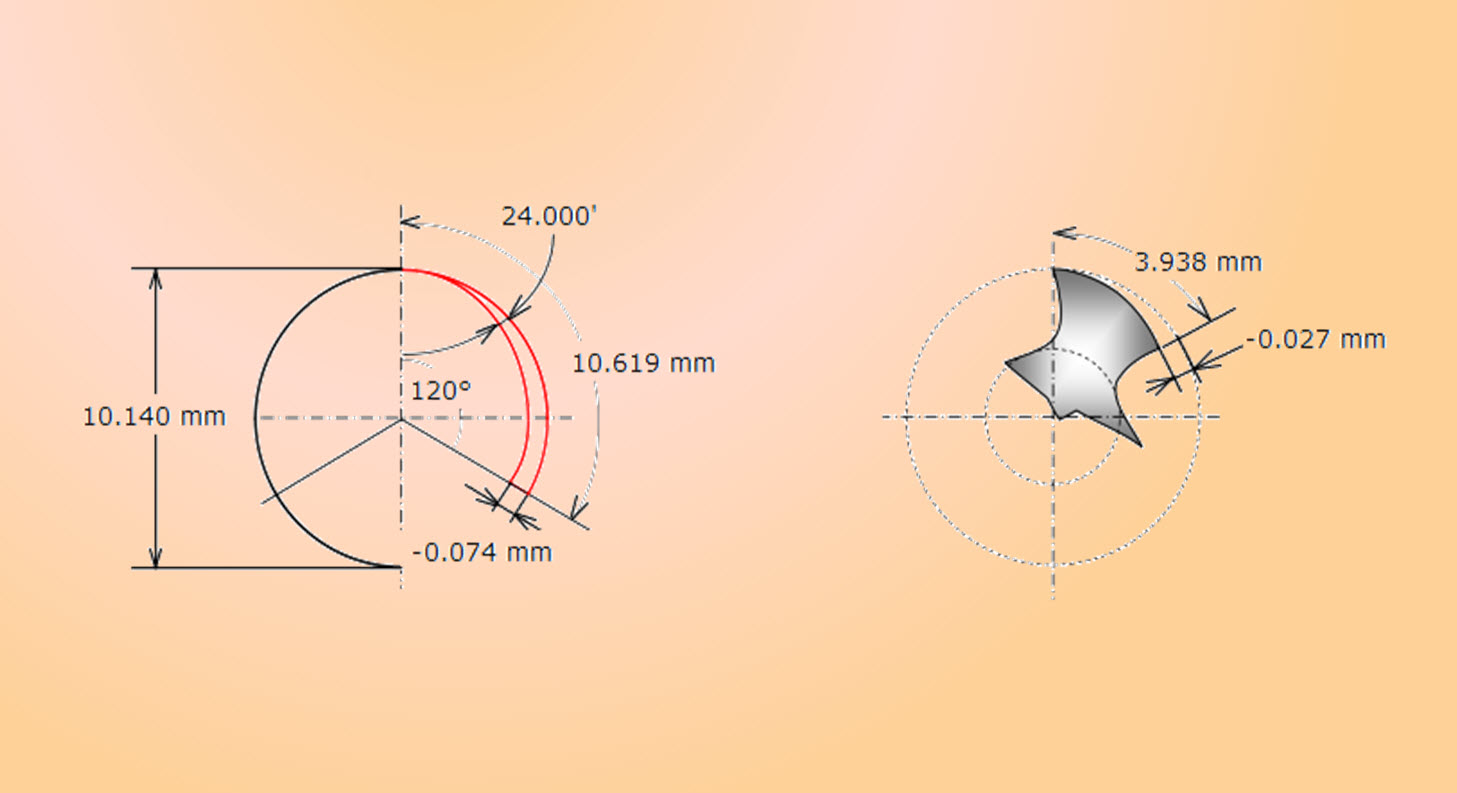

Division relief in thread

Thread bridge width: 3.900 mm

Thread relif angle: 24.000′

Division: 120°

Division relieve in thread: -0.074 mm

Radians on division: 10.619 mm

Radians thread bridge width: 3.938 mm

Relief after thread bridge width: -0.027 mm

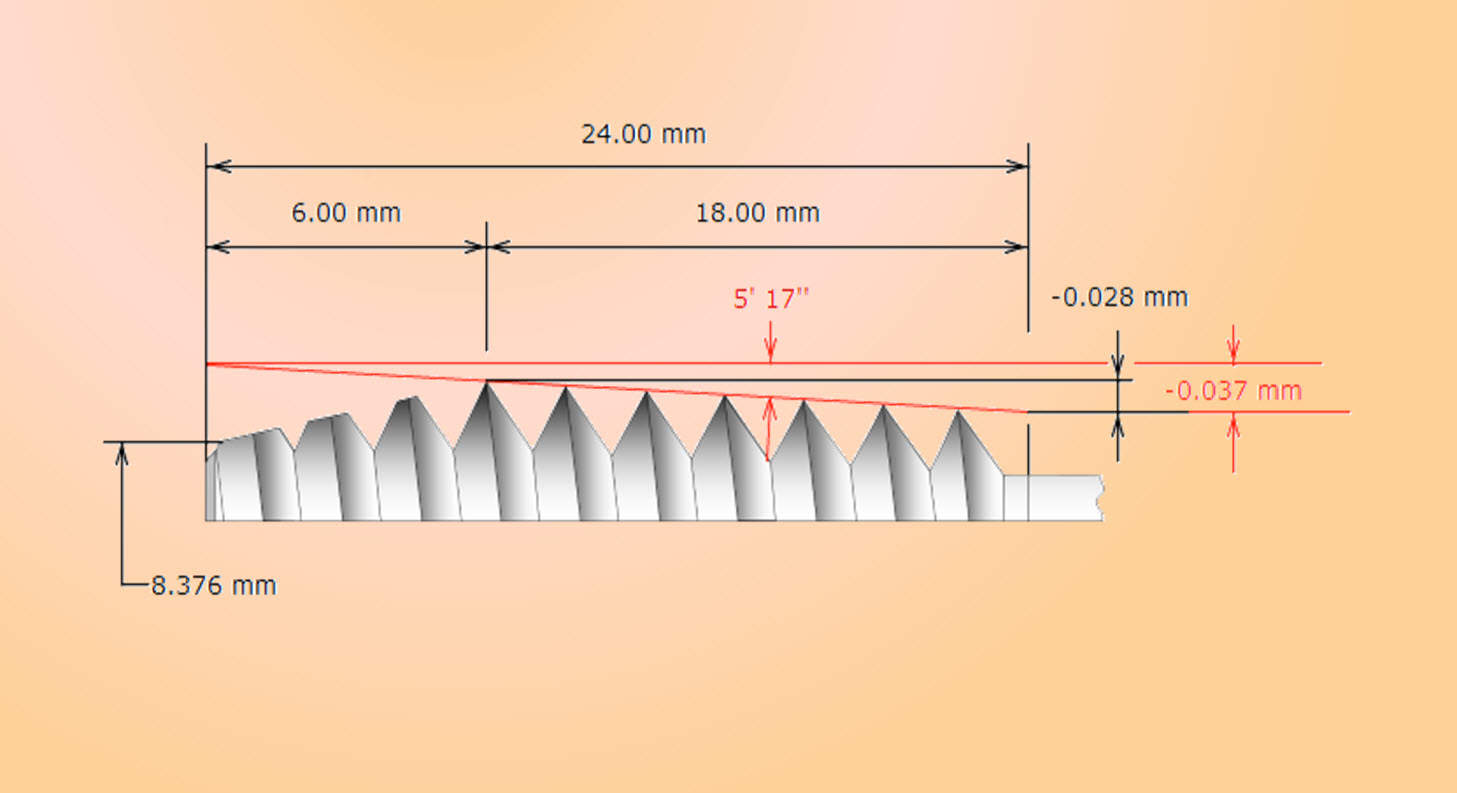

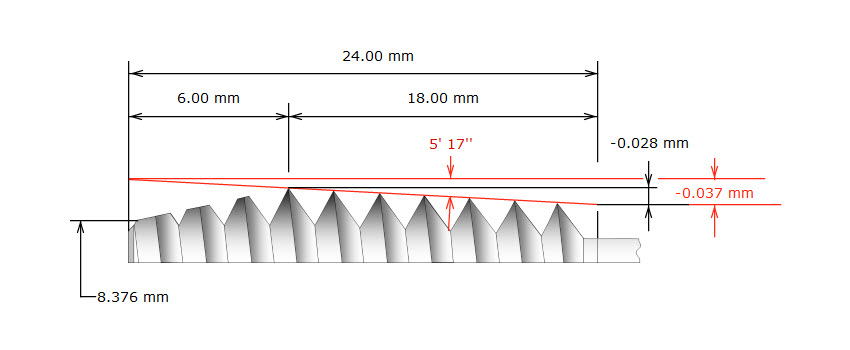

Back tape

Thread length: 24 mm

Taper angle: 5.300′

Diameter of back tape: -0.075 mm

Radius of back tape: -0.037 mm

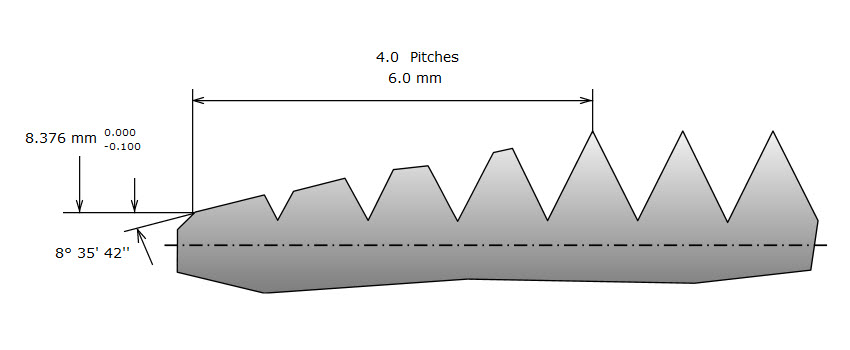

Chamfer

Chamfer diameter: 8.376 mm

Tolerance chamfer diameter: 0.000 mm

XXXXXXXXXXXXXXXXXXXIII-0.100 mm

Chamfer length: 4.0 pitches / 6.00 mm

Setting angle: 8.598° / 8° 35′ 42″

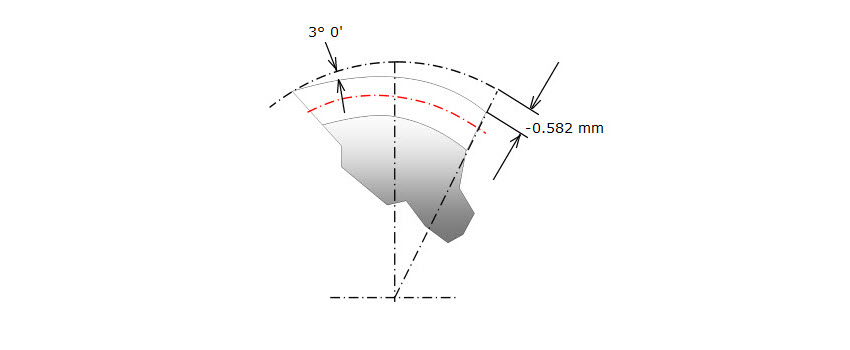

Thread relef angle: 3.00° / 3° 0′ 0″

Division relef: -0.582 mm

Designation

Marking 1st line: M 10.00 mm X 1.50 mm

Marking 2nd line: B/4 DIN 376

Marking 3rd line: Calculated by TapPro

• All value in blue are proposed by the Genius

• All value in white are calculated by TapPro

• All values in gold are to be entered by the developer

• Overview of the calculation

Thread type

Designation: M 10.00 X 1.50 6H Th-hole

Creator: Philippe Manigley

Type: 3000

Group number: 3000 PM Classe53

Artical number: 250.10.15.1

Drawing number: 2000.150.10.15.1

Test protocol number: 2000.150.10.15.2

Date: 27.05.2021

Time: 10:25:15

Thread tolerance: 6H

Thread type: M

Flank angle: 60°

Half flank angle: 30°

Hole type: Th-hole

Thread diameter: 10.00 mm

Pitch: 1.50 mm

Multiple thread: 1

Thread blank diameter: 10.30 mm

Profile shift «X»: 0.000 mm

Over mass: 0.000 mm

Chamfer form: B

Chamfer pitch: 4

Flute number: 3

Alternated teeth: No

Right/left: RH

Cutting material: HSSE-PM

Cutting steel hardness: HRc 66

Hardening process: Vaccum

Class: Classe53

Genius number: 1101

Coating: TICN

Coating thickness: 3 μ min. to 5 μ max.

MG-Group: MG07, MG09, MG11, MG12

Spiral point

Chamfer diameter: 8.376 mm

Spiral point cutter angle: 8° min. / 10° max.

Angle A: 9°

Angle S: 6°

Spiralpoint length: 8.25 mm

X: 6.00 mm

Inclinaton: 9° min. / 11° max.

Thread dimensions

Outside diameter: 10.140 mm 0.000 / -0.050

Upper value: 0.140 mm

Lower value: 0.090 mm

TD2 Bolt: 0.140 mm

TD2 Screw: 0.180 mm

Flank diemeter: 9.026 mm

Size tolerance 1: 0.042 mm

Size tolerance 2: 0.070 mm

Middle flank diameter: 9.082 mm

Theorical wire diameter: 0.866 mm

Mesuring wire diameter: 0.900 mm

Mesuring wire flanc diameter: 10.471 mm min.

XXXXXXXXXXXXXXXXXXXXIII10.499 mm max.

Mesuring wire flanc radius: 5.235 mm min.

XXXXXXXXXXXXXXXXXXXI5.249 mm max.

Wire axis: 9.585 mm

Core diameter: 8.317 mm max.

Pitch angle: 3.010° / 3° 0′ 32″

Half flank angle: 30°Leer

Half flank tolerance: 25′

Inclined position Cw: 0.0019 mm

Division relief in thread

Thread bridge width: 3.900 mm

Thread relif angle: 24.000′

Division: 120°

Division relieve in thread: -0.074 mm

Radians on division: 10.619 mm

Radians thread bridge width: 3.938 mm

Relief after thread bridge width: -0.027 mm

Back tape

Thread length: 24 mm

Taper angle: 5.300′

Diameter of back tape: -0.075 mm

Radius of back tape: -0.037 mm

Chamfer

Chamfer diameter: 8.376 mm

Tolerance chamfer diameter: 0.000 mm

XXXXXXXXXXXXXXXXXXXIII-0.100 mm

Chamfer length: 4.0 pitches / 6.00 mm

Setting angle: 8.598° / 8° 35′ 42″

Thread relef angle: 3.00° / 3° 0′ 0″

Division relef: -0.582 mm

Designation

Marking 1st line: M 10.00 mm X 1.50 mm

Marking 2nd line: B/4 DIN 376

Marking 3rd line: Calculated by TapPro

• All value in blue are proposed by the Genius

• All value in white are calculated by TapPro

• All values in gold are to be entered by the developer